The Thick Metal metal type allows you to model physically thick metal. All other metal types are modeled as having zero thickness where the entered thickness value only affects the metal loss calculations. The Thick Metal type allows you to more accurately model the true 3D characteristics of thick conductors. Using a thick metal model not only allows for proper modeling of loss, but also includes the EM effects of physically thick metal, such as coupling between closely spaced conductors.

Since thick metal increases both your processing time and memory requirements, it should only be used when necessary. Metal is considered to be thick metal when its thickness is comparable to other dimensions in the circuit such as the width of a conductor or gap between conductors.

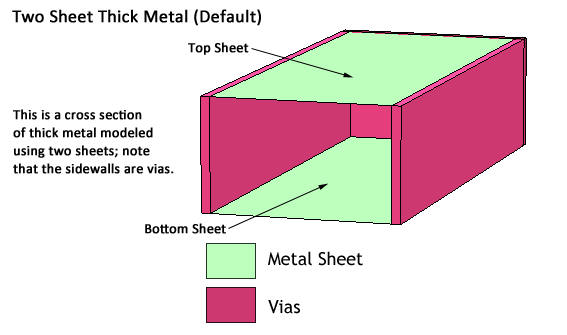

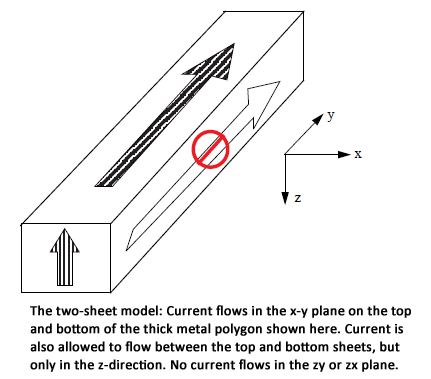

When using thick metal, the structure is approximated by two or more infinitely thin sheets of metal. The Number Of Sheets setting defines how many sheets of horizontal metal are in the vertical stack that models the thick metal. For the typical two sheet model, one sheet represents the top surface of the structure and a second sheet represents the bottom surface of the structure. Vias are placed automatically around the perimeter to allow current to flow between the sheets. An example using two sheets is illustrated below.

For Number Of Sheets set to two sheets, the current travels on only the top and bottom surface of the thick metal. Current on the sides of the thick conductor can be approximated by using three or more sheets.

For most cases, using the default of two sheets provides a high accuracy solution. However for very tightly coupled lines, where the gap between the lines is much less than the metal thickness, the coupling between them may be underestimated. In these cases, you may need to increase the number of sheets. However, increasing the number of sheets increases the memory requirements and processing time.

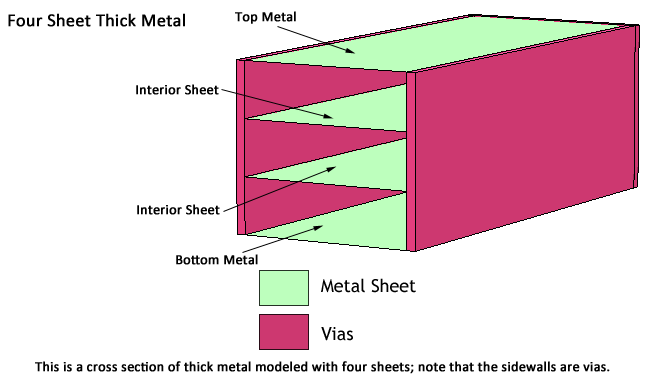

Increasing the number of sheets adds more layers of infinitely thin metal between the top and bottom metal sheet. A cross section of a four sheet model is shown below.