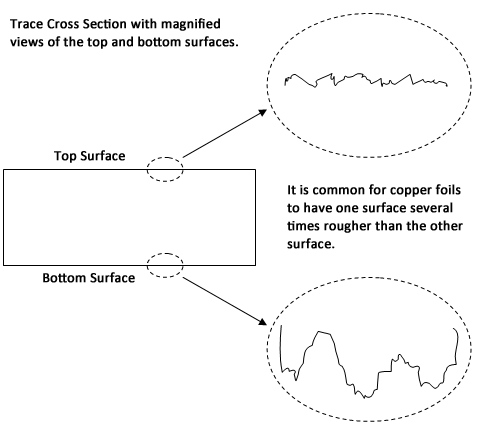

Many circuit manufacturing processes produce planar metallization with rough surfaces. Depending on how the metallization is formed, one, or both, of the trace metal surfaces could be relatively rough. The Rough Metal type allows you to capture this surface roughness effect in your model.

At frequencies where the skin depth is comparable or smaller than the surface roughness dimension, the current flow is forced into the surface roughness region and this introduces excess resistance and excess inductance in your traces. This in turn increases the insertion loss and insertion phase of your planar transmission lines.

You do not necessarily need to use the Rough Metal type as you create models in Sonnet. However, when you are working with circuits that are very sensitive to these transmission line characteristics, it will improve your model accuracy. Generally, models with rough metal surfaces and narrow trace widths, that operate at high frequency (above 5 GHz) are good candidates for the Rough Metal model.

The Sonnet Rough Metal Model is based on an extensive study of surface roughness effects in printed circuit board conductors. See reference [1] in Sonnet References for a detailed description.

It may be valid to apply Rough Metal to conductors from other manufacturing processes, as long as the surface roughness effect that you are trying to capture is a function of the trace top and bottom surfaces.

To define a Rough Metal type you must first obtain the metal trace top and bottom surface roughness in RMS microns for the metal. Often circuit material suppliers provide this information directly or you can ask the manufacturing group producing your physical parts.

Surface roughness can also exist on ground plane metal. If you are using an analysis box cover to represent a ground plane, you can define a Rough Metal type and apply it to the cover. Rough Metal types assigned to a box cover are limited to a thin cross section.

Surface roughness can also exist on ground plane metal. If you are using an analysis box cover to represent a ground plane, you can define a Rough Metal type and apply it to the cover. Rough Metal types assigned to a box cover are limited to a thin cross section.

Care should be taken when using the results in a time domain simulation, as the Rough Metal results are not guaranteed to be causal.

Care should be taken when using the results in a time domain simulation, as the Rough Metal results are not guaranteed to be causal.

There are two variations of the Rough Metal: Thin and Thick. The Thin option models the metal as a single “zero thickness” (2D sheet), like the Normal loss model but with the surface roughness effect. With this option, the user must specify a Current Ratio.

The Thick option models the metal as two sheets of current; one for the top surface and one for the bottom surface of the planar metal trace. This is very similar to the Thick Metal loss model (with two sheets), with the surface roughness effect. See Thick Metal for additional details on modeling metal thickness.